ProTXcoat 356

Epoxy Concrete Repair Quartz ( Incl 302 Primer)

Epoxy based Quartz reinforced concrete repair screed

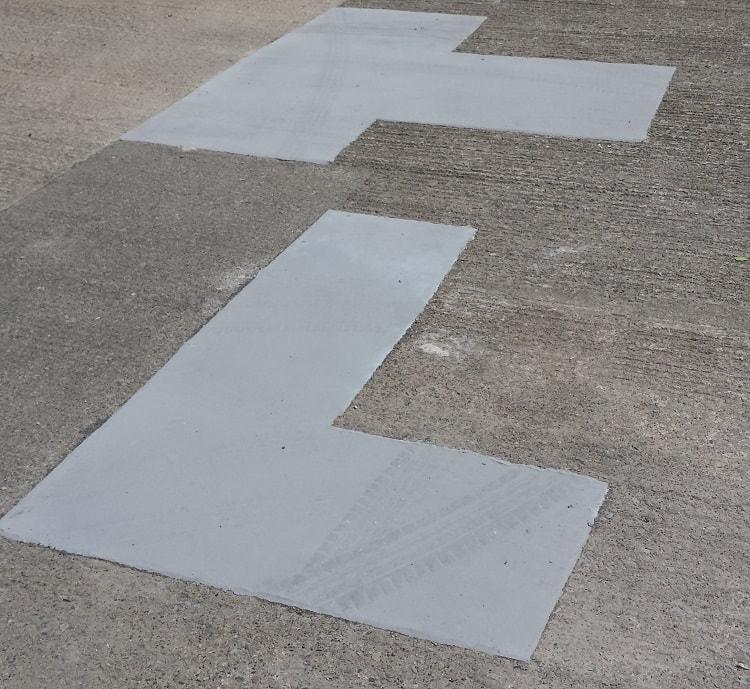

356 is a high performance mortar designed for use as a heavy duty repair system for concrete and mineral surfaces.

356 is based on a blend of solvent free epoxy resins and polyamino amine adducts reinforced with a special blend of silica quartz minerals and inorganic fillers which have been specially selected to provide optimum application and performance properties together with a high level of adhesion, abrasion, impact and chemical resistance.

356 is a unique repair system, easy to apply by trowel or float with no shrinkage or volume change during cure and is ideal for the repair of damaged concrete, sills, lintels, steps, ramps, walkways and loading bays..

TECHNICAL SPECIFICATIONS

Surface preparation

All dirt and loose friable material should be removed, and the surface cut back to a sound edge. Any exposed re-bars must be fully exposed and treated with a ProTXcoat 302 Solvent free primer.

Abrasion of surfaces will cause dusting and therefore all loose dust should be vacuumed clear before the application commences.

Priming

Whilst 350 can be used without a primer, on certain very porous surfaces a coat of the mixed 350 resins should be applied to prime/ seal the surface.

Two parts of base resin should be mixed with one part of activator by volume and the mixed system brushed into the prepared surface.

Mixing

350 is a three component material which must be mixed together prior to use.

When mixing the complete unite aggregate component should be removed from the outer container, which is then used as the mixing container. The base and activator containers should be emptied into the mixing container and mixed until homogeneous. The aggregate should now be added and thoroughly mixed into the base resins to ensure complete wetting out.

Applicaiton

The mixed 350 should be applied by float or trowel to the prepared surface with the material being pressed firmly onto the surface then finished by float to give a smooth surface.

When applied at 4mm 350 will provide a coverage rate of 0.5 m2 per 5 kg unit.

When applied at 6mm 350 will provide a coverage rate of 0.3 m2 per 5 kg unit.

All equipment must be cleaned IMMEDIATELY after use with MEK Solvent Cleaner.

NOTE: The minimum temperature of application is 5oC (50oF).

Volume Capacity

450 cc (29 cu ins) per kilo

Physical constants

| Mixing Ratio | Resin | Aggregate |

| 1 | 9 By weight | |

| Appearance | Resin Base | Straw Coloured liquid |

| Resin Activator | Amber fluid | |

| Aggregate | Natural or light grey | |

| Drying & Cure Times at20°C(68°F) | UsableLife | 25minutes |

| Initial Set | 6 hours | |

| Min Overcoat | 6 hours | |

| Max Overcoat | 8 hours | |

| Volume Solids | 100% | |

| V.O.C. | Nil | |

| Shelf Life | Use within 5 years of purchase. Store in original sealed containers at temperatures between 5°C (40°F) and 30°C (86°F). |

Physical properties

| Abrasion Resistance | 145 mgm weight loss per 1000 |

| ASTM D4060 | cycles – 1 kg load – CS17 Wheel |

| Impact Resistance | 1.8 Joules (16 in lbs) |

| ASTM D256 | |

| Direct Pull Adhesion | 35 kg/cm2 (500 psi) – concrete |

| ASTM D4541 | (Concrete Failure) |

| Compressive Strength | 880 kg/cm2 (12500 psi) |

| ASTMD695 | |

| Tensile Strength | 200 kg/cm2 (2832 psi) |

| ASTMD307 | |

| Tensile adhesion | 36 kg/cm2 (500 psi) |

| ASTMD4541 | |

| Flexural Strength | 490 kg/cm2 (7000 psi) |

| ASTMD790 | |

| Flexural Modulus of elasticity | 1.3×105 kg/cm2 |

| (1.3x104MPa) 1.87 x 106 psi | |

| Adhesion Strength | 100% Concrete |

| 28kg/cm2 kg/cm2 >400psi | |

| Shrinkage | Nil |

| ASTM C246 |

Health and safety

As long as normal good practice is observed 356 can be safely used.

Protective gloves should be worn during use.

A fully detailed Safety Data Sheet is either included with the material or is available on request.

Packaging

Supplied in 10kg- 45kg packs

The information provided int his Product Data Sheet is intended as general guide only and should not be used for specification purposes. The information is given in good faith but we assume no responsibility for the use made of the productorthis information because this is outside the control of the company. Users should determine the suitability of the product for their own particular purposes by their own tests.