ProTXcoat ProTXStick

- Metal filled epoxy rebuilding compound

- No solvent

- No Shrinkage

- Fast curing

- Epoxy resin based

- Putty stick

- Can be machined once cured

Rebuild damaged metal surfaces

- Pipework

- Pump casings

- Tank seams

- Tank surfaces

- GRP surfaces

- Bond metal to metal

TECHNICAL SPECIFICATIONS

Surface Preparation

Heavy contamination due to oil or grease must be removed. All loose material, rust and surface contaminants, including existing coatings, must be removed and the surface roughened by using an angle grinder, needle gun or abrasive blasting. Where grinding is used, the surface should be cross-scored to improve adhesion. Care must be taken, when angle grinding, to avoid polishing rather than roughening metal surfaces. Surface- es should be carefully degreased again using an appropriate cleaner, cloths should be frequently changed to avoid spreading contamination. On deeply pitted surfaces or porous castings

Mixing

Before mixing, hands should be treated with a suitable barrier cream or lightweight disposable gloves should be worn. Sufficient product to complete the repair should be cut or broken from the stick. This should then be twisted and kneaded until a uniform colour is achieved with no streaks. The two components are colour coded to ensure complete mixing is achieved when the colour is uniform

Applicaiton

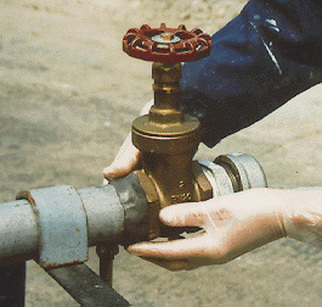

Prepared surfaces should be dry. The mixed material should be pressed firmly onto the prepared area, working the material into any cracks and surface defects.

When ProTXStick is being used to repair leaking pipes, the flow through the pipe should be discontinued until the repair is made and the ProTXStick is set. Any leaking fluid must be wiped from the prepared surface to render the surface as dry as possible before undertaking the repair

Technical properties

| Technical Properties | ||

| Mixing ratio | Ready to use | |

| Volume solids | 100% | |

| Colour | Mid grey base Black activator | |

| Unit sizes | 125gm | |

| Curing times (20°C) | ||

| Pot life | 25 mins | |

| Touch dry | 2 hours | |

| Full chemical resistance | 5 days |

Technical Specification

| flexural Strength | |

| 230kg/cm2 (3250 psi) | ASTM D790 |

| Compressive Strength | |

| 350kg/cm2 (5000psi) | ASTM D695 |

| Tensile shear adhesion | |

| 45kg/cm2(650psi) | ASTM D1002 (Grit Blasted) |

| Heat Disortion | |

| 40°c (96°F) | ASTM D648 |

| Hardness (shore D) | |

| 85 | ASTM D2246 |

| Corrotion Resistance | |

| 5,000 hrs | ASTM B117 |

Health and safety

Please ensure good practice is observed at all times. Protective gloves, goggles & a disposable coverall must be worn during the mixing and application of this product. Before mixing and applying the material ensure you have read the fully detailed Safety Data Sheet.

Legal Notice

The data contained within this Product Specification is furnished for information only and is believed to be reliable at the time of issue. We cannot assume responsibility for results obtained by others over whose methods we have no control. It is the responsibility of the customer to determine the products suitability for use. ProTXcoat accepts no liability arising out of the use of this information or the product described herein.