ProTXcoat 101CP

Ceramic Paste

Two Component Ceramic Engineering Repair Compound

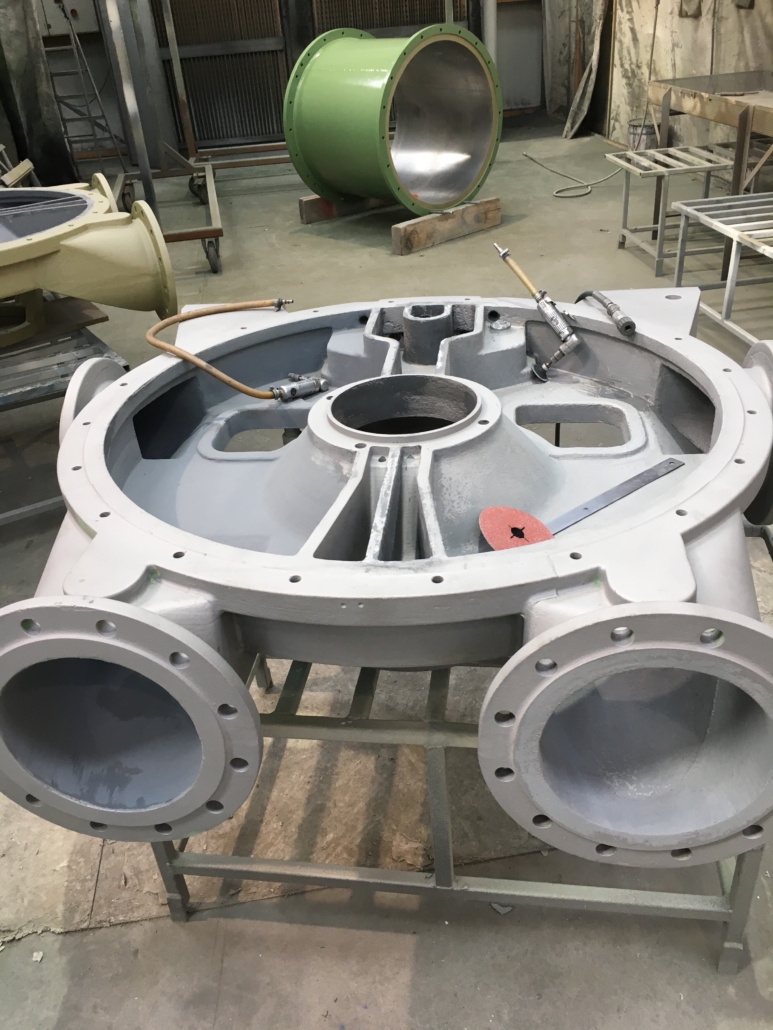

101CP is a high performance multipurpose metal repair compound specifically developed for rebuilding metal components in a fluid flow environment damaged by erosion and corrosion.

101CP is formulated on a complex range of epoxy resins combined with a polyamine curing system reinforced with hardened ceramic fillers to enhance abrasion resistance, corrosion and chemical resistance of the whole system.

101CP can be applied to any damaged component in one easy application and is ideal for rebuilding pump bodies, impellers, propellers, guide vanes, valves, tube sheets, water boxes, rudders, heat exchangers etc.

Before proceeding, please read the following information carefully to ensure that the correct application procedure is fully understood.

TECHNICAL SPECIFICATIONS

Surface preparation

Heavy contamination due to oil or grease must first be removed using MEK (Methyl Ethyl Ketone)Surfaces should then be abrasive blast cleaned to a minimum

Sa21⁄2 – Sa3 BS7079 Part A1 : 1989 or equivalent with a blast profile of 75 – 125 microns corresponding to ‘Rough’ in ISO 8503/1. All loose abrasive dust and debris must be blown clear or vacuum cleaned away.

Equipment that has been salt impregnated due to service conditions should first be wet blasted then dry abrasive blasted and checked for presence of salts, this process should be repeated until the salts are removed.

Alternatively, surfaces should be warmed with a blow torch or similar to bring salts up to the surface. The surface should once again be blast cleaned. This procedure must be repeated until no further sweating of impregnated salt is evident.

Mixing

101CP is a two component solvent free material comprising base and activator components which must be mixed together prior to use.

Measure 3 volumes of base component and 1 volume activator component onto a clean mixing board or other suitable surface. The two components should then be thoroughly mixed until completely streak free.

The mixed material should be used within 25 minutes of mixing at 20°C (68°F). This time will be reduced at higher temperatures and extended at lower temperatures.

Applicaiton

Application should not be carried out at temperatures below 5°C nor when relative humidity exceeds 85% or when the surface to be repaired is less than 3°C above the dew point.

The mixed material should be pressed firmly onto the prepared area, care should be taken to avoid air entrapment on deeply pitted surfaces. Application should be carried out as soon as possible after surface preparation is complete, and certainly the same day, otherwise flash blasting will be necessary before application.

When Reinforcing Tape is being used to strengthen the repairs the tape should either be impregnated with 101CP or the tape should be laid over the 101CP surface and stippled into the material before it cures, then additional 101CP applied over the surface.

In areas where a second layer of 101CP is required, this application must be carried out within the initial set time for the first layer, if this is not possible surfaces will require thorough abrasion or abrasive blasting prior to any subsequent material being applied.

Machining of 101CP will cause excessive tool wear so care should be taken to finish the repair to the required size or dimensions. Formers treated with Release Agent can be used to minimize machining.

Volume Capacity

417cc (26cu ins) per kilo

Detailed working recommendations are available from the

Technical Centre on request.

Physical constants

| Mixing Ratio | Base | Activator |

| 3 | 1 By Volume | |

| 5 | 1 By Weight | |

| Appearance | Base | Grey Paste |

| Activator | Light Grey Paste | |

| Drying & Cure Times at 20°C(68°F) | Usable Life | 25 minutes |

| Initial Set | 60 minutes | |

| Machining | 2hours | |

| Full Mechanical | 3 days | |

| Volume Solids | 100% | |

| V.O.C. | Nil | |

| Shelf Life | Use within 5 years of purchase. Store in original sealed containers at temperatures between 5°C (40°F) and 30°C (86°F). | |

| Temperature Resistance | Dry Heat | 200°C |

| Intermittent wet | 120°C | |

| Wet immersion | 70°C | |

| Coverage Rates | ||

| 1kg (2.2lb) mixed product will give the following coverage rates: | 0.406m2at 1mm 4.3ft2 at 40mil | |

| 0.203m2at 2mm 2.2ft2 at 80mil | ||

| 0.135m2at 3mm 1.45ft2 at 1/8” | ||

| Food Contact | Meets USDA requirements for incidental food contact. Meets FDA requirements CFR 21.175.300 for food contact.

Canadian Food Inspection Agency – Accepted Product. |

Physical properties

Compressive Strength 1055 kg per cm2 (15000psi) ADTM D695

Tensile Shear Adhesion 175 kg per cm2 (2500psi) ASTM D1002 (Grit Blasted Steel)

Flexural Strength 700 kg per cm2 (10000psi) ASTM D790

Heat Distortion Temperature 90°C (194°F) ASTM D648

Hardness (Rockwell R) 100 ASTM D785

Abrasion Resistance 0.06 ml per 1000 cycles – ASTM D4060 1 kg load/CS17 Wheel

Nuclear Decontamination Excellent

BS 4247 Part 1

Health and safety

As long as normal good practice is observed 101CP can be safely used.

Protective gloves should be worn during use.

A fully detailed Safety Data Sheet is either included with the material or is available on request.

Packaging

Supplied in 1kg, 3kg and 30kg packs

The information provided in this Product Data Sheet is intended as a general guide

only and should not be used for specification purposes. The information is given in

good faith but we assume no responsibility for the use made of the product or this

information because this is outside the control of the company. Users should

determine the suitability of the product for their own particular purposes by their

own tests.